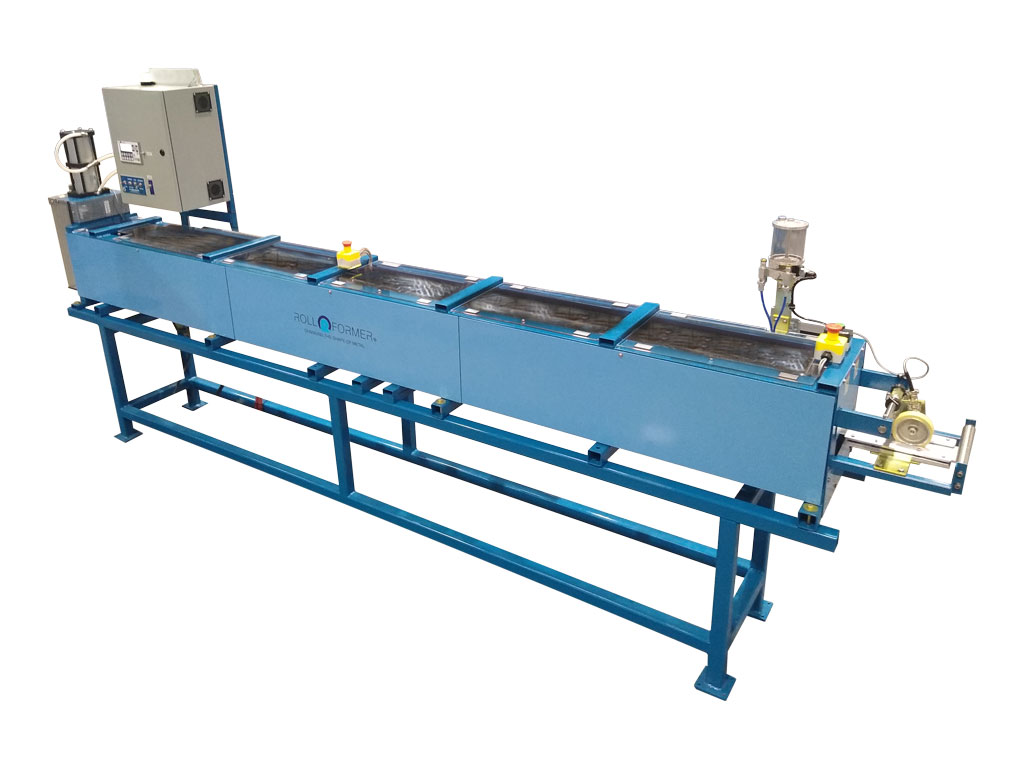

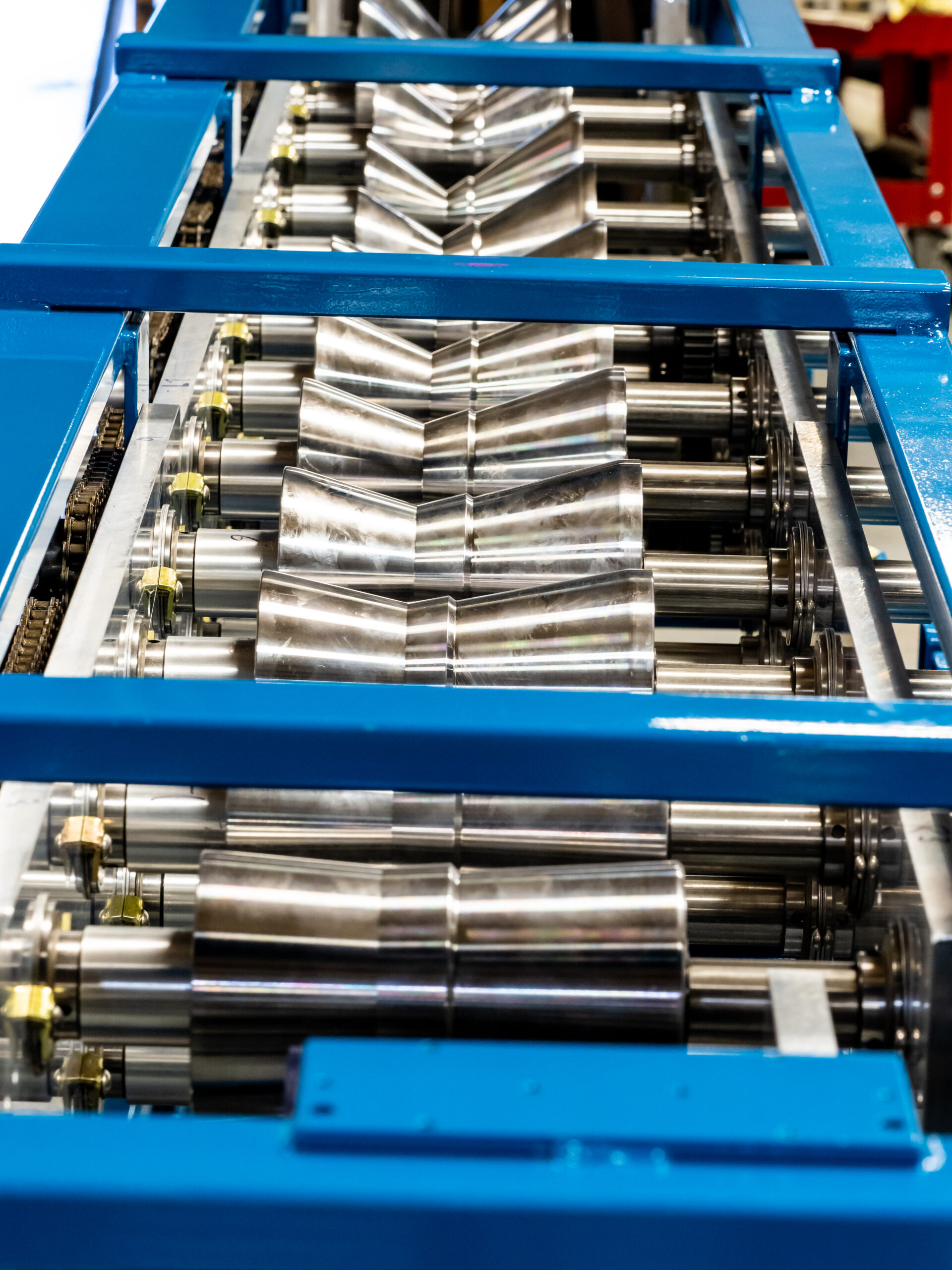

Designed and Manufactured in the USA with Stainless Steel to Hardened Tool Steel Forming Rolls with or w/o Chrome Plating, Sealed Bearings, Stainless Steel Shafting, Hydraulic Drive and Shear or AC Drive Motor System and Air Powered Shear, and Digital Controllers for fully automatic operation. Typical thickness capacities range from 30 to 16 gauge on Steel and .019″ to .060″ on Aluminum.

The benefit of owning your trim machine is you no longer have to deal with the constant rising prices of trim, and long lead times. Trim machines also allow you to “free up” your brake or folder for other projects, and there is no limitation on the length of pieces.