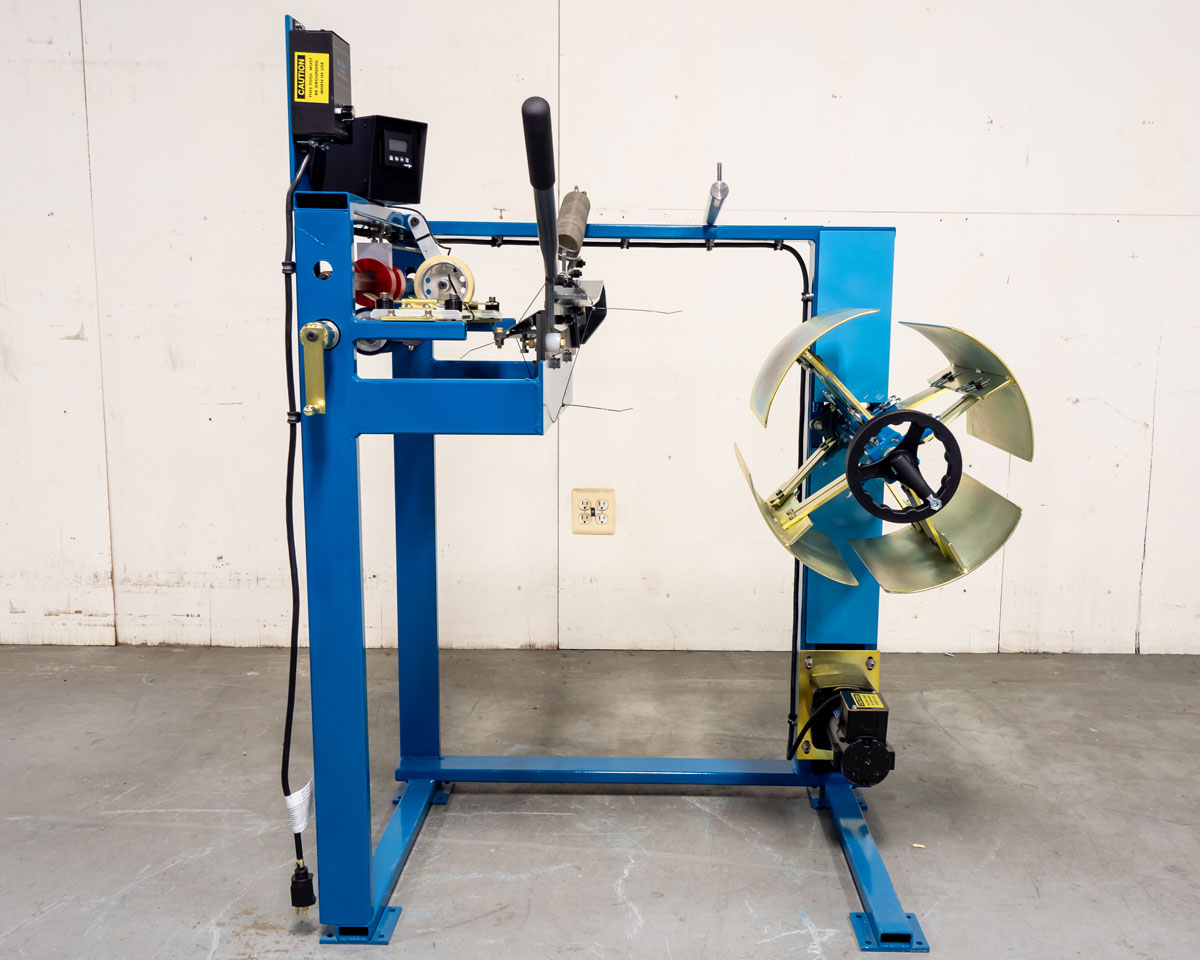

Standard Features

- Easy and quick set-up

- Retractable pinch rolls for easy material loading and unloading

- Safe/simple adjustable speed control

- Up to 200 feet/minute recoiling speed

- Digital Controller for semi-automatic coil winding

- Non-damaging “Drum Style” Recoiler Spindle

- Six turn collapsible 16″ diameter mandrel

- 300 lb. maximum recoiling capacity

- Film dispenser stage to wrap finish coils

- Heavy tubular steel framing

- Small footprint – 2′ X 3′ X 4′

Options & Accessories

- V-Groove Caster Wheel Set for Rack System

- Standard Caster Wheel Set